分类导航

新闻

联系我们

济南宏大隆昌商贸有限公司

联系电话:15066683078

联系地址:济南市天桥区历山北路黄台装饰不锈钢市场北区28号

提高铜门高耐磨性的两个方法

来源:http://www.jnqianfu.com 日期:2023-01-13 发布人:admin浏览次数:0

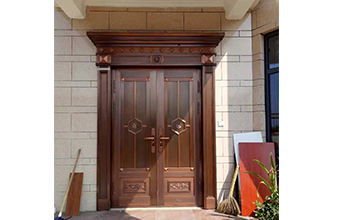

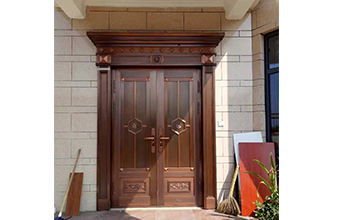

在很多人眼里,铜门是一个很高档的入口。给人以金碧辉煌、厚重沉稳、庄严神圣之感。铜门曾用于深室和重要场所。它不仅象征着地位,而且是维持门内和平的坚实屏障。那么山东铜门耐磨性高要如何确保呢?接下来由小编来讲解一下吧,希望能够对大家有所帮助。

In the eyes of many people, the copper door is a very high-end entrance. It gives people a feeling of resplendence, solemnity and sanctity. Copper doors have been used in deep rooms and important places. It not only symbolizes status, but also is a solid barrier to maintain peace inside the door. So how to ensure the high wear resistance of Shandong copper door? Next, let's talk about it. I hope it can help you.

1、众所周知,即使铜门天生耐腐蚀,也应该赋予它一定的强度。铜本身是防腐材料,但铜门通常在加工过程中继续防腐,以获得更大的性。具体工艺如下,在铜门表面进行钢丝拖动,然后清洗表面,以及做好钝化操作。以防止面板轮廓与相关物质接触,保持铜的原色。

1. It is well known that copper doors should be endowed with certain strength even if they are naturally corrosion resistant. Copper itself is a corrosion resistant material, but copper doors usually continue to be corrosion resistant during processing to obtain greater safety. The specific process is as follows: drag the steel wire on the surface of the copper door, then clean the surface, and do a good job of passivation. To prevent the panel outline from contacting with related substances and maintain the primary color of copper.

2、铜门厂家的磷化处理少要进行两次,以便在铜表面形成保护膜。铜门经过精心喷涂保护漆,以增强其防腐性能,然后在160℃下烘烤。在这个过程中,铜工业将被喷洒和烘烤两次,以有效提升其防腐性能。铜门是通过自然冷却过程中的一系列步骤完成的。而其他辅助材料的铜门也提高了防腐水平。

2. The phosphating treatment of the copper door manufacturer shall be carried out at least twice to form a protective film on the copper surface. The copper door is carefully sprayed with protective paint to enhance its corrosion resistance, and then baked at 160 ℃. In this process, the copper industry will be sprayed and baked twice to effectively improve its anti-corrosion performance. The copper door is completed through a series of steps in the natural cooling process. The copper doors made of other auxiliary materials also improve the anti-corrosion level.

即使它具有天然的抗腐蚀性,也应该赋予它一定的强度,为了更,铜门在加工过程中往往会进一步防腐。具体工艺流程如下:

Even if it has natural corrosion resistance, it should also be given a certain strength. In order to be safer, copper doors will often be further anti-corrosion during processing. The specific process flow is as follows:

1.先对铜门表面进行拉丝处理,然后进行多次表面清洁和相关钝化操作,使隔板表面的面板轮廓与相关腐蚀性材料接触,以保持铜的原始颜色。

1. The surface of the copper door shall be brushed first, and then the surface shall be cleaned and passivated for many times to make the panel outline of the clapboard surface contact with the relevant corrosive materials, so as to maintain the original color of the copper.

2.磷化处理应少进行两次,以便在铜表面形成保护膜。

2. Phosphating treatment shall be carried out at least twice to form a protective film on the copper surface.

3.仔细喷涂防护漆以增强其防腐性能,然后在160℃的高温下烘烤。在这个过程中,铜工业还将进行两次喷涂和烘烤,以提高其防腐性能。

3. Carefully spray protective paint to enhance its anti-corrosion performance, and then bake at 160 ℃. In this process, the copper industry will also carry out two times of spraying and baking to improve its anti-corrosion performance.

4.在自然冷却过程中,经过一系列步骤,终完成一扇门。

4. In the process of natural cooling, a door is finally completed after a series of steps.

以上是有关提高铜门高耐磨性的两个方法的全部内容,如果您还有疑问,可在我们的网站http://www.jnqianfu.com上进行咨询,感谢您的理解与支持!

The above is the full content of two methods to improve the high wear resistance of copper doors. If you have any questions, please visit our website http://www.jnqianfu.com Thank you for your understanding and support!

- 上一篇:铜门选锁时需要关注四个要点

- 下一篇:铜门的好坏程度可通过什么方法来判断